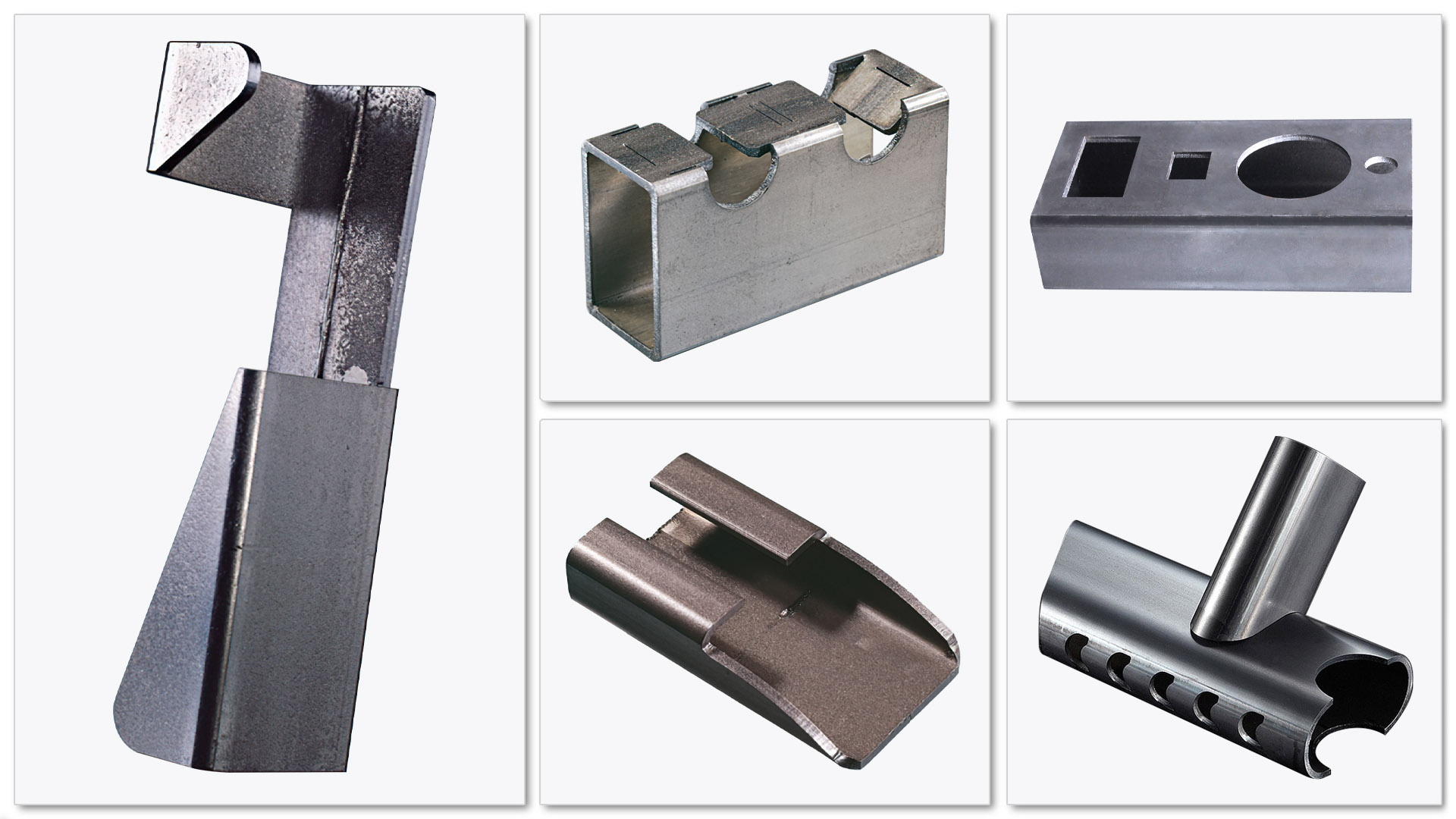

A WPB 6025 CE sorozatot főként kör alakú csövek, négyzet alakú csövek és egyéb csövek megmunkálására használják. különleges alakú termékek fajtái.

Modell :

WPB 6025A lineáris tengely helyzetének ismétlődő pontossága :

±0.03mmA lineáris tengely maximális sebessége :

98m/minA forgástengely maximális sebessége :

100rpmA forgatási tengely helyzetének ismétlődő pontossága :

8 arc-minCsőátmérő tartomány :

Φ20-219mm □20-220mmMaximális feldolgozási kapacitás :

45kg/mFerde vágás :

optionalOperációs rendszer :

Smart managerWPB 6025 CE sorozatú lézeres csővágó gép

A WPB 6025 CE sorozatú lézeres csővágó gép közepes teherbírású csövek vágására készült. Egyedi, nagy szájnyílással és nagy teherbírású, oldalra függesztett tokmánnyal rendelkezik, maximális teherbírása 270 kg. A gép standard félautomata/teljesen automatikus adagolórendszerrel van felszerelve. A adagolótámasz nagy szorítóerő-rögzítővel van felszerelve, hogy biztosítsa a csőadagolás központosítását. A adagolóoldalt egy szervovezérlésű lebegő tartó, a kirakodóoldalt pedig egy szervovezérlésű lapos lebegő tartó támasztja meg. A ferde vágási funkció opcionális. Megfelel az európai és amerikai CE/UL tervezési szabványoknak, teljesen lezárt vágóterülettel, hármas biztonsági reteszeléssel az elektromechanikus és lézeres vágás abszolút biztonsága érdekében.

Jellemző

Oldalra szerelt ágyszerkezet

Az L alakú, közepes teherbírású ágyrács masszív, stabil és rendkívül tartós, maximális teherbírása akár 270 kg.

Fúró és menetfúró funkció

ESzénacél anyagokhoz fúró és menetfúró funkcióval felszerelve, M4-től M10-ig terjedő meneteket támogat stabil pontossággal és hatékonysággal.

Ferde vágás

A ferde vágás funkció opcionálisan konfigurálható, lehetővé téve a precíz él-előkészítést csőhegesztéshez és egyéb speciális gyártási követelményekhez.

Rövid anyagok kirakodó rendszere

Opcionális rövid anyagok szállítóplatform-rendszere. Lehetővé teszi a hosszú és rövid anyagok elkülönített kirakodását, így a folyamat hatékonyabbá válik. és időtakarékos.

Zagy kirakodása

A vágás után keletkező zagy automatikus eltávolítása, lehetővé téve a folyamatos, megszakítás nélküli rakodást.

Működési szoftver

■A Smart Manager legújabb verziója egy európai fejlesztésű CNC szoftver, amelyet az olasz CNC rendszerekkel való zökkenőmentes integrációra terveztek. Fejlett lézervágási adatbázissal rendelkezik, amely lehetővé teszi a vágási paraméterek valós idejű beállítását az optimális vágási minőség elérése érdekében.

■Az új algoritmus gyorsabb válaszidőt tesz lehetővé.

■A rendszer akár 15 rétegű vágási paraméter és 25 rétegű perforációs módszer konfigurálását támogatja.

Vágási minta